automotive sheet metal forming Automotive Sheet Metal Forming Techniques. Forming techniques such as bending and stamping allow you to shape materials to form the right auto part. Bending. Sheet metal bending is a common technique that uses a press brake machine to deform a sheet metal and create angles and curves. The machine can apply force at predetermined points on the .

YAOHUA JXH Ilntroduction: Junction load cell Box FOor scale GND IN Junction box GND ( JXH-xC ) ( JXH-xB Able to connect with strain gauge load cell at resistance of 350—800 ohm, excitation 3—15V DC. Standard Function: Selection of connection mode: JXH-xB for parallel mode; JXH-xC for serial mode x for quantity of load cell: 4, 6, 8

0 · sheet metal layout drawings

1 · sheet metal forming types

2 · sheet metal forming process pdf

3 · sheet metal forming press dies

4 · sheet metal forming pdf

5 · forming sheet metal by hand

6 · forming process in sheet metal

7 · bulk deformation vs sheet metal forming

Yaquis Metal Fabricator Inc. | Metals. Yaquis Metal Fabricator Inc. Categories. Metals. 137 Puente Ave City of Industry CA 91746-2302 (626) 407-8490 (626) 563-4957; Send Email; Visit site; About Us. Fabricators welding and machine shop. Share

For automotive metal forming, the blank is often made of sheet metal, which can be stamped, cut or bent into a shape needed for an . In this article, we’ll give you the lowdown on sheet metal forming, including the various processes, suitable materials, and its pros and cons. What is Sheet Metal Forming? Also known as sheet metal fabrication, sheet metal .

For automotive metal forming, the blank is often made of sheet metal, which can be stamped, cut or bent into a shape needed for an automobile's body. Alternatively, it can be a solid block of metal in a cubical or lens-like shape.

Most autobody metal work is performed with relatively simple and traditional tools like body hammers and dollies. Add a few really straight-forward but clever tools that speed work and enhance capabilities, and you have the basis for tackling most projects in this field. In this article, we’ll give you the lowdown on sheet metal forming, including the various processes, suitable materials, and its pros and cons. What is Sheet Metal Forming? Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components.

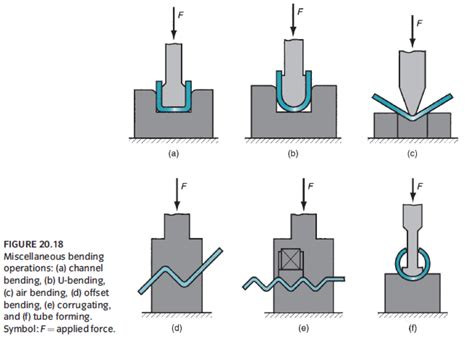

Automotive Sheet Metal Forming Techniques. Forming techniques such as bending and stamping allow you to shape materials to form the right auto part. Bending. Sheet metal bending is a common technique that uses a press brake machine to deform a sheet metal and create angles and curves. The machine can apply force at predetermined points on the ..describe different forming processes, when they might be used, and compare their production rates, costs and environmental impacts .calculate forming forces, predict part defects (tearing, wrinkling, dimensional inaccuracy), and propose solutions .explain current developments: opportunities and challenges Objectives

sheet metal layout drawings

Automotive manufacturers leverage sheet metal forming to fabricate body panels, chassis components, and exhaust systems, enabling the production of vehicles with optimal strength-to-weight ratios and aesthetic appeal.

Sheet metal forming is a complex process that involves the application of forces and deformations to a sheet of metal to create a desired shape. During this process, several defects can occur that can impact the quality of the final product. Sheet metal forming is a core element in the crafting of products from cars to appliances – involving skill, experience and technologically advanced tools. This article provides an insight into how this intricate process works, discussing techniques used with metals to create superior quality components.

Automotive sheet metal must be durable, corrosion-resistant, and capable of withstanding the demanding conditions of the automotive industry. Selecting the correct sheet metal for the application is critical to a comprehensive design.

Sheet Metal Services for Automotive Products Our team specializes in both short run and mass volume projects. From the prototype stage to the production line, we can expertly handle it all.

sheet metal forming types

For automotive metal forming, the blank is often made of sheet metal, which can be stamped, cut or bent into a shape needed for an automobile's body. Alternatively, it can be a solid block of metal in a cubical or lens-like shape.

Most autobody metal work is performed with relatively simple and traditional tools like body hammers and dollies. Add a few really straight-forward but clever tools that speed work and enhance capabilities, and you have the basis for tackling most projects in this field. In this article, we’ll give you the lowdown on sheet metal forming, including the various processes, suitable materials, and its pros and cons. What is Sheet Metal Forming? Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components.

Automotive Sheet Metal Forming Techniques. Forming techniques such as bending and stamping allow you to shape materials to form the right auto part. Bending. Sheet metal bending is a common technique that uses a press brake machine to deform a sheet metal and create angles and curves. The machine can apply force at predetermined points on the ..describe different forming processes, when they might be used, and compare their production rates, costs and environmental impacts .calculate forming forces, predict part defects (tearing, wrinkling, dimensional inaccuracy), and propose solutions .explain current developments: opportunities and challenges Objectives

Automotive manufacturers leverage sheet metal forming to fabricate body panels, chassis components, and exhaust systems, enabling the production of vehicles with optimal strength-to-weight ratios and aesthetic appeal. Sheet metal forming is a complex process that involves the application of forces and deformations to a sheet of metal to create a desired shape. During this process, several defects can occur that can impact the quality of the final product.

Sheet metal forming is a core element in the crafting of products from cars to appliances – involving skill, experience and technologically advanced tools. This article provides an insight into how this intricate process works, discussing techniques used with metals to create superior quality components. Automotive sheet metal must be durable, corrosion-resistant, and capable of withstanding the demanding conditions of the automotive industry. Selecting the correct sheet metal for the application is critical to a comprehensive design.

sheet metal forming process pdf

5 axis cnc parts supplier

5 axis cnc machine for sale uk

Whether you want shiny metallic silver fabric or glittery metallic gold fabric, we’ve got all the metallic fabrics you’ll need to make your quilt shine bright. One of the best things about metallic fabric is you can use it for, well, nearly anything you want!

automotive sheet metal forming|sheet metal forming process pdf